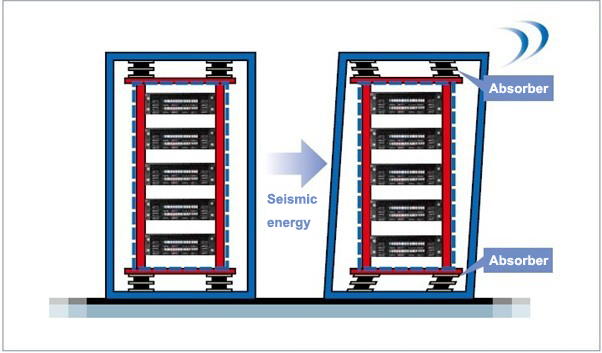

Shock-proof cabinet solution

In order to ensure that the equipment meets the seismic requirements, the double-layer frame structure damping method is usually adopted.

Combined with the following methods:

A. The cabinet frame is made of stainless steel.

B. Welding to strengthen the ribs as needed;

C. Diagonal support to base;

D. All joints are welded;

E. The thickness of the cabinet frame base is 3mm.

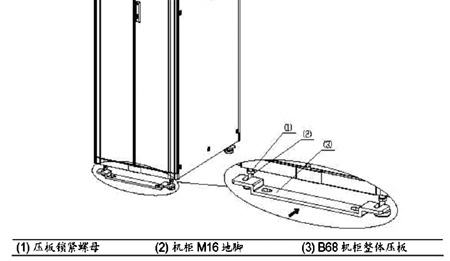

Engineering construction reinforcement treatment:

Design and install anti-seismic pressure plates to ensure that the cabinet is securely placed on the concrete floor or the surface of the support, and secure the cabinet with appropriate fasteners. As shown below:

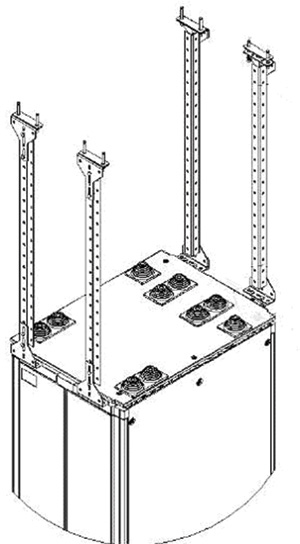

The upper part of the cabinet is reinforced with channel steel to further improve the anti-seismic capability of the cabinet. As shown below:

Adapt to the use of environmental conditions:

A. Environmental conditions during installation and before operation:

– Normal ambient temperature: -20 ~ 31.2 ° C; extreme ambient temperature: -29.2 ~ 35.8 ° C

– Relative humidity: 0 to 100%

– Air: contains salt and dust

– Atmospheric pressure: 0.098 ~ 0.104Mpa

Mechanical stress: Vibration of support parts: 10 ~ 2000Hz, amplitude: 0 ~ 30μm, acceleration: 0.2g

B. Environmental conditions during operation:

– Normal ambient temperature: 5 to 40 ° C; extreme ambient temperature: 5 to 55 ° C

– Relative humidity: 0 to 100%

– Air: contains salt and dust

– Atmospheric pressure: 0.098 ~ 0.104Mpa

Mechanical stress: Vibration of support parts: 10 ~ 2000Hz, amplitude: 0 ~ 30um, acceleration: 0.2g

Other considerations:

The cabinet must include a member to secure it to a supporting structure.

For the inserted devices in the cabinet and the devices to be installed on guide rails, a mechanical limiter must be provided as required to maintain the positioning firmness.

All devices connected to or adjacent to the cabinet must be installed in such a way that the performance of the cabinet may exceed the allowable level due to seismic events.